Chapter 7:

H2O2 Material Compatibility

• All wetted surfaces should be made of materials that are compatible with hydrogen peroxide. The wetted

area or surface of a part, component, vessel or piping is a surface which is in permanent contact with or is

permanently exposed to the process fluid (liquid or gas).

- Hydrogen Peroxide storability (and more generally, compatibility) is based off of the rate of decomposition when in contact with a given material.

- Hydrogen Peroxide Material compatibility is generally ranked through a class structure.

- Class 1: Materials Satisfactory for Unrestricted use with H2O2 ‒ Class 2: Materials Satisfactory for Repeated Short-Time Contract with H2O2.

- Maximum of 4 hours at 160 F or 1 Week at 70 F.

- Class 3: Materials Satisfactory for Short-Term Contact Only.

- Less than 1 minute at 160 F and 1 hour at 70 F for unpressurized systems. Single use only.

- Class 4: Not recommended for use with H2O2.

- Class 1: Materials Satisfactory for Unrestricted use with H2O2 ‒ Class 2: Materials Satisfactory for Repeated Short-Time Contract with H2O2.

•The class system is only used to provide a relative guide, and is not a perfect system.•Surface finish and surface treatment has a large impact on compatibility.•Most Metals need to be passivated prior to service with HTP.

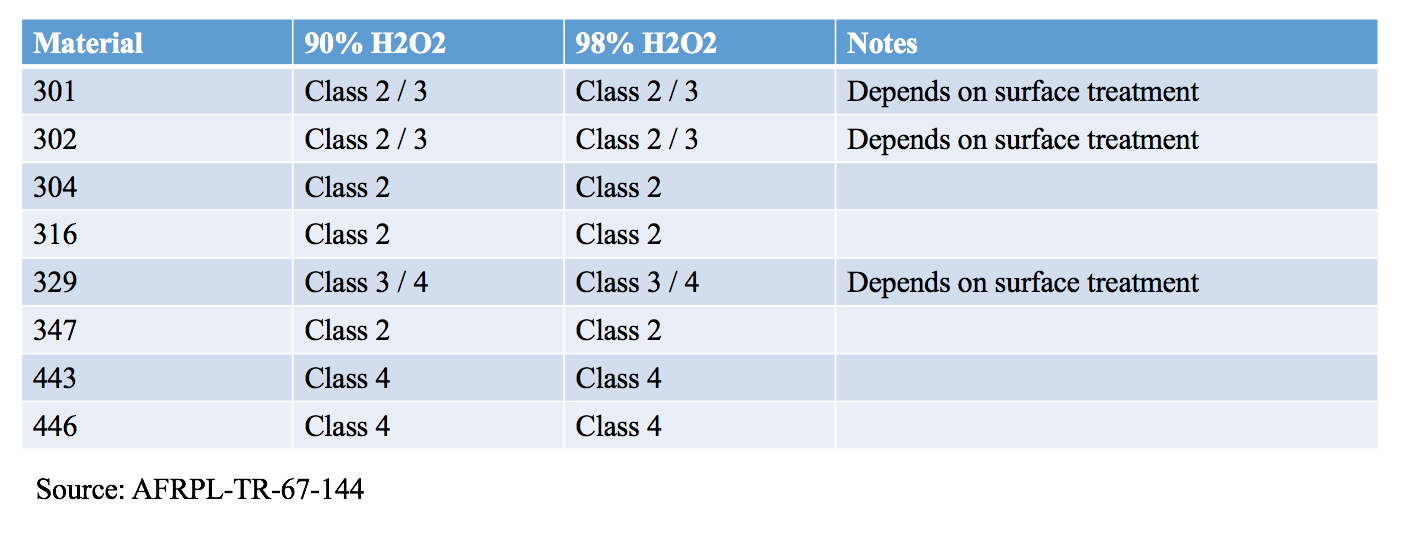

--> Stainless Steel Compatibility Chart

--> Aluminum Compatibility Chart

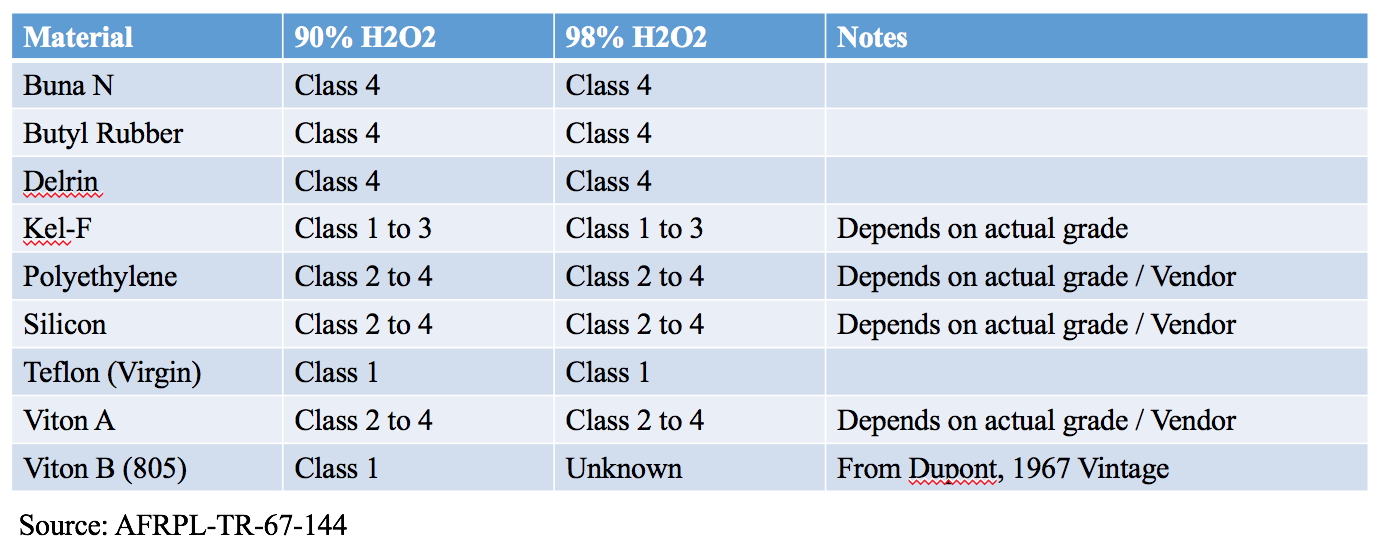

--> Seals and Elastomers Compatibility Chart

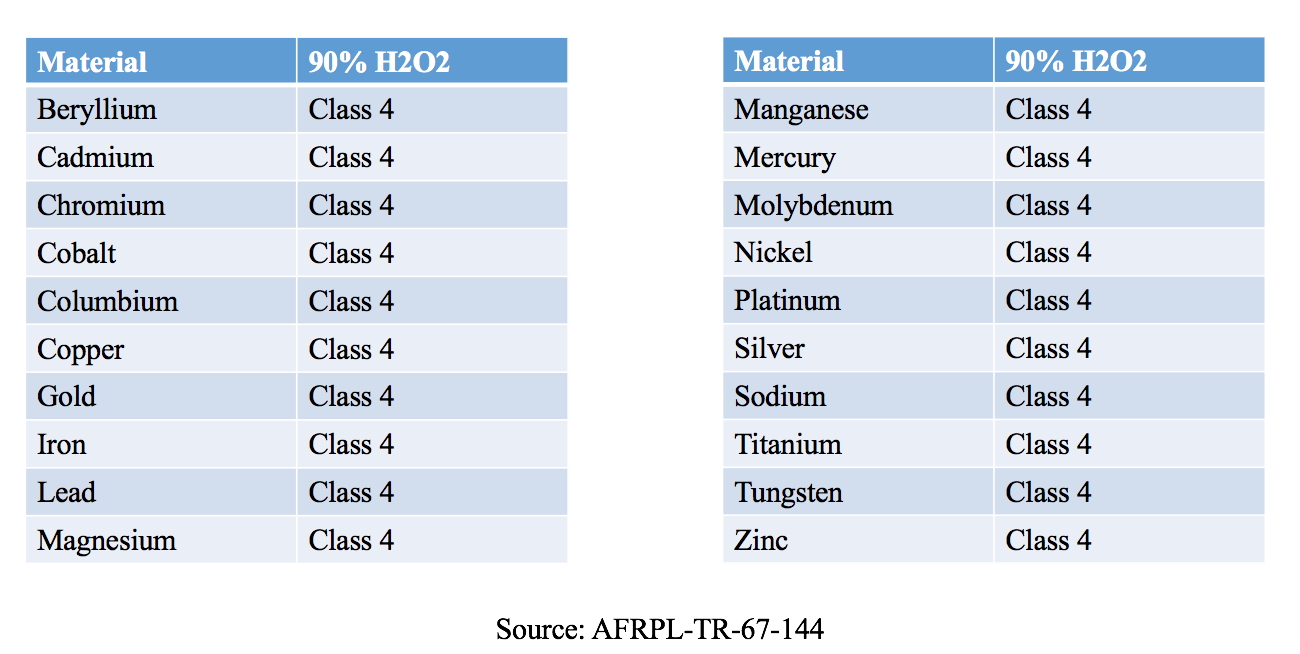

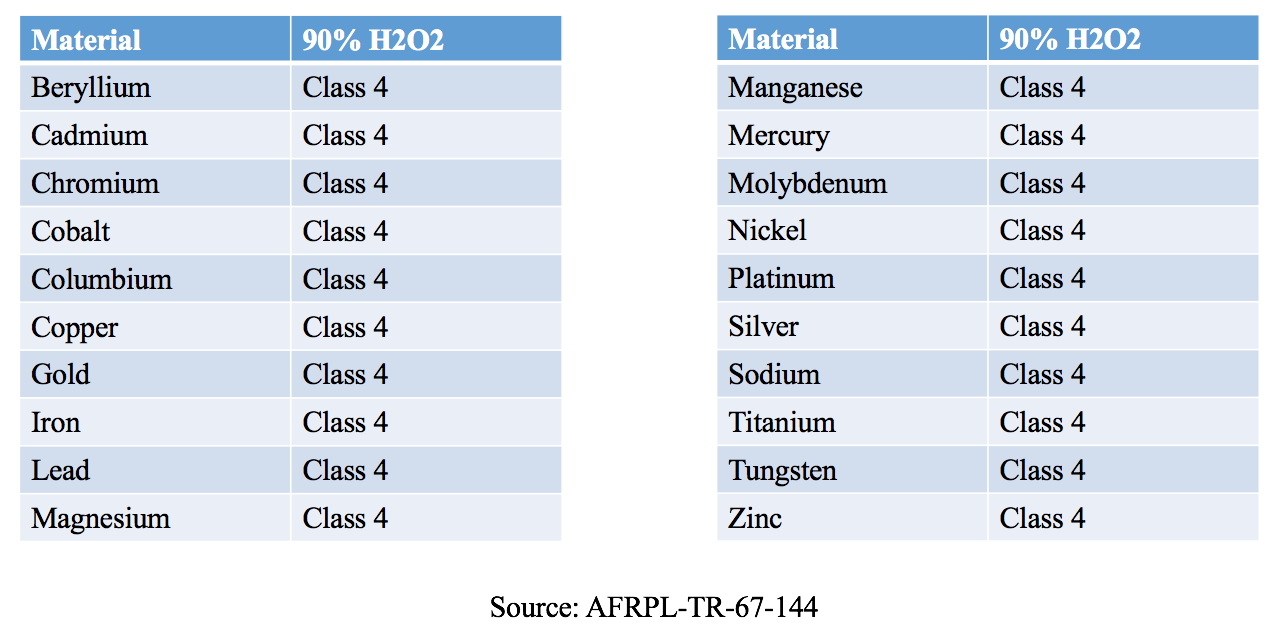

--> Metals to Avoid

General Material Compatibility Checklist

| Material | Compatibility 10% H2O2 |

Compatibility 30% H2O2 |

Compatibility 50% H2O2 |

Compatibility 100% H2O2 |

|---|---|---|---|---|

| 304 stainless steel | B2 - Good | B2 - Good | B2 - Good | B2 - Good |

| 316 stainless steel | B - Good | B - Good | A2 - Excellent | A2 - Excellent |

| ABS plastic | A - Excellent | N/A | N/A | A - Excellent |

| Acetal (Delrin®) | D - Severe Effect | D - Severe Effect | D - Severe Effect | D - Severe Effect |

| Aluminum | A - Excellent | A - Excellent | A - Excellent | A - Excellent |

| Brass | N/A | N/A | N/A | D - Severe Effect |

| Bronze | B1 - Good | B1 - Good | B1 - Good | B1 - Good |

| Buna N (Nitrile) | D - Severe Effect | D - Severe Effect | D - Severe Effect | D - Severe Effect |

| Carbon graphite | C - Fair | C - Fair | C - Fair | C - Fair |

| Carpenter 20 | C - Fair | B - Good | B - Good | D - Severe Effect |

| Cast iron | C - Fair | B - Good | N/A | B - Good |

| Ceramic Al203 | N/A | N/A | N/A | A - Excellent |

| Ceramic magnet | A - Excellent | A - Excellent | A - Excellent | A - Excellent |

| Copper | D - Severe Effect | D - Severe Effect | D - Severe Effect | D - Severe Effect |

| CPVC | A - Excellent | A - Excellent | A - Excellent | A - Excellent |

| EPDM | A - Excellent | B - Good | B - Good | D - Severe Effect |

| Epoxy | C1 - Fair | B - Good | N/A | A - Excellent |

| Hastelloy-C® | A - Excellent | A - Excellent | A - Excellent | A - Excellent |

| Hypalon® | D - Severe Effect | D - Severe Effect | D - Severe Effect | D - Severe Effect |

| Hytrel® | N/A | N/A | N/A | N/A |

| Kel-F® | A - Excellent | B - Good | A - Excellent | B - Good |

| LDPE | A - Excellent | C2 - Fair | C2 - Fair | C2 - Fair |

| Natural rubber | B - Good | C - Fair | C - Fair | C - Fair |

| Neoprene | D - Severe Effect | D - Severe Effect | D - Severe Effect | D - Severe Effect |

| NORYL® | A2 - Excellent | A2 - Excellent | N/A | A - Excellent |

| Nylon | C1 - Fair | D - Severe Effect | D - Severe Effect | D - Severe Effect |

| Polycarbonate | A2 - Excellent | A2 - Excellent | A2 - Excellent | A - Excellent |

| Polypropylene | A - Excellent | B1 - Good | B1 - Good | B1 - Good |

| PPS (Ryton®) | A - Excellent | A1 - Excellent | N/A | C - Fair |

| PTFE (Teflon®) | A - Excellent | A - Excellent | A - Excellent | A - Excellent |

| PVC | A1 - Excellent | A1 - Excellent | A1 - Excellent | A - Excellent |

| PVDF (Kynar®) | A - Excellent | A - Excellent | A1 - Excellent | A1 - Excellent |

| Silicone | A - Excellent | B - Good | B - Good | B - Good |

| Titanium | A - Excellent | B1 - Good | A - Excellent | B - Good |

| Tygon® | B - Good | B - Good | B - Good | B - Good |

| Viton® | A - Excellent | A - Excellent | A - Excellent | A - Excellent |

Ratings -- Chemical Effect

N/A = Information Not Available. |

Explanation of Footnotes

|